06.06.2025

Service from programming through to component

Schabmüller taps into MAPAL’s expertise in aluminium

Until a few years ago, Schabmüller produced cylinder head covers for the VW 3.0-litre V-group engine in quantities of up to 320,000 a year. The components, for which Schabmüller also handles installation, are still produced, but the volume has already decreased. However, other major orders have arrived, making the company less dependent on the combustion engine.

“The production of suspension parts has begun since then. This gives us the opportunity to diversify ourselves in this direction”, says managing director Helmut Häckl. “Our business has developed and pursued precisely this goal.” However, the new components pose challenges for Schabmüller, too.

When becoming involved in the production of suspension parts, Schabmüller had whole new experiences. Particularly for electric vehicle components, projects are sometimes postponed, originally planned quantities are not reached, or additional changes are required at short notice before series production begins. Häckl knows why: “Up until the end, the OEMs gather experience in load tests for vehicles that are becoming increasingly heavier due to the weight of the batteries. This means that certain components are designed in a more stable way to cover all borderline situations.” Stephan Streck, technical consultant at MAPAL, explains using the example of a hub carrier. As issues with stiffness arose during driving. Almost at the last minute, another surface had to be machined and a stiffening rib was added.

Schabmüller has to plan the facilities and prices for the components before their exact design is known, which always presents the manufacturer with challenges. “Cycle time is the decisive factor for getting an order”, says Häckl.

MAPAL INVOLVED FROM THE OUTSET

To get a better grip on these short-term changes and continue optimising overall production, Schabmüller decided to bring MAPAL on board already at the CAD/CAM programming phase. “We have a very cooperative partnership with MAPAL and appreciate their rapid response times”, explains Häckl. “So we felt good about expanding our cooperation to CNC programming and simulation.” MAPAL is already involved in tool design for new projects and in charge of tool management. These services are tailored to the client’s needs. These include tool scheduling, pre-adjustment, dispensing and reconditioning, technical support for series production, tool and cycle time optimisations, and tool life optimisations.

Schabmüller stopped programming itself back in 2018. “For CAD/CAM, we need specialists who know this subject matter inside out”, says Häckl. “If we only tackle two to four new projects a year, a staff member can’t be fit here.” Schabmüller has used the machine manufacturer’s services for programming from time to time since then. However, there was no option for 3D simulations, which meant the manufacturer knew that not all options for optimising cycle times were being used.

Now that MAPAL is involved from the beginning, this has changed. NC programming, simulation and tool management are now perfectly intertwined. For instance, simulation data is included in tool planning, which helps detect potential collisions at an early stage. It is possible to respond immediately to component changes by the OEMs before the start of production. Modifications are made in the 3D simulations before the tools are finished. Streck explains the importance of simulation: “If you don’t catch adverse changes in good time, costs can run into the five figures.”

Simulation also plays a key role in optimising machining. For instance, it shows approach angles that can be used to improve material removal. Data from the computer can also be used to reduce tool wrapping. “This type of detail is much easier to detect in simulations than looking through the window into the machine”, says Streck.

FORGED PARTS, NOT CAST ALUMINIUM

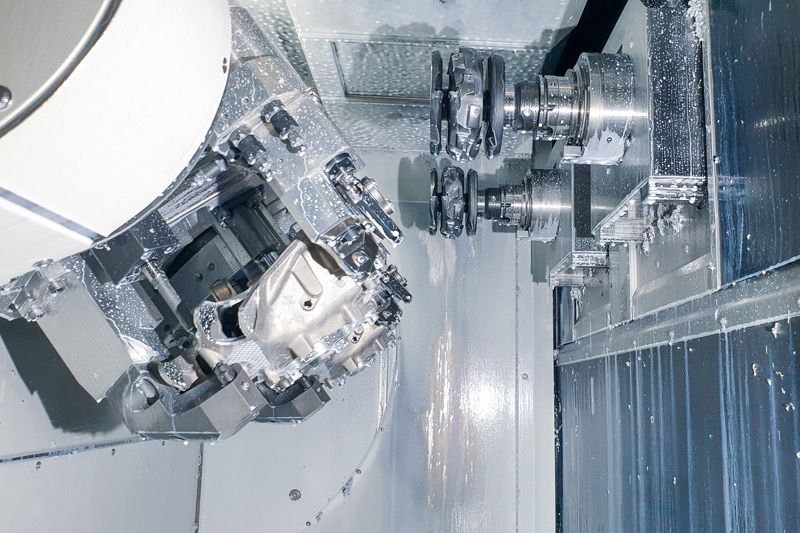

The suspension parts involve a shift in starting material from die cast aluminium to forged aluminium. Forged parts have much higher load indicators than cast parts. The higher stability is required in particular for electromobility. However, this also increases machining requirements to achieve the desired cycle time. Material removal and thus the volume to be machined are much higher here, which requires adapted milling strategies.

The material properties have also changed, as Stephan Streck explains: “Compared to aluminium cast parts, the forged material has a much lower silicon content. This means that the chip doesn’t break well, long chips are produced in machining, and we need to deal with smeared blades. All of MAPAL’s aluminium machining expertise is required to find solutions here.” Schabmüller currently uses forged aluminium to produce some of the hub carriers, steering knuckles and control arms made in Großmehring.

HIGH-VOLUME MILLING CUTTER NEOMILL-ALU-QBIG USED BEFORE ITS MARKET LAUNCH

Another aspect of improving processes is MAPAL bringing new tools on board as soon as they are available and promise benefits. As application engineer Eugen Bien notes, the new indexable insert milling cutter NeoMill-Alu-QBig was used at Schabmüller before it even officially came on the market.

This new indexable insert milling cutter from MAPAL stands out for its top performance in high-volume aluminium milling. It is designed for use at speeds up to 35,000 min-1 to achieve the maximum possible material removal rate. For a tight fit despite high centrifugal forces, screws with increased tensile strength are used to hold the indexable inserts firmly in the prismatic seat. MAPAL has fitted the tool body with a fine balancing system to protect the machine spindle and achieve high surface finishes where possible. In addition, focus was placed during development on low cutting forces and highly precise indexable inserts.

From the three coatings available, MAPAL technicians chose a diamond coating for the machining of mould casting at Schabmüller. During operation, the machine operator rotates the indexable inserts with their two cutting edges directly on the machine. MAPAL retips the milling cutter in the setting room. One benefit of the ductile solid carbide inserts of the NeoMill-Alu-QBig in comparison to the milling cutters with brazed PCD blades used before: They break out less quickly when there are sand residues from the casting mould on the raw part.

However, there is another aspect that is decisive for the user, as Häckl affirms: “In production, we achieved shorter cycle times with the NeoMill-Alu-QBig, as we were able to attain greater values for cutting speed and feed. For this, we were readily willing to accept shorter tool lifes.”

Switching to the NeoMill-Alu-QBig required a different milling strategy and higher central chip thickness. The values measured by MAPAL are testament to the success achieved as a result. The adjustments implemented with higher cutting parameters, the switch from circular milling to helix milling, and the improved machining conditions resulted in a cycle time saving for this machining operation of 54%. The new tool made it possible to increase the feed per tooth from an average of 0,14 mm to 0,32 mm.

In the comprehensive tool set for machining a hub carrier, the NeoMill-Alu-QBig is one of the few standard tools, but it plays a crucial role for the cycle time, as Eugen Bien puts it: “Use of the NeoMill-Alu-QBig constitutes around 30% of the total machining time.” The focus is on the roughing of the component, but the tool also produces surfaces in finished part quality.

ROOM TO GROW IN FUTURE

Contact

Mathias Ostertag Public Relations mathias.ostertag@mapal.com Phone: +49 7361 585 3566